Gas monitoring in energy applications

The oil, gas and mining sectors play an essential role in the global economy, providing vital energy and raw materials. However, extracting and processing these resources presents complex challenges, particularly when it comes to managing gas emissions. Accurate gas measurement in these industries is essential to optimize production efficiency, mitigate environmental consequences and safeguard the well-being of workers.

This article examines the importance of gas measurement in the oil, gas and mining sectors, highlighting its benefits and its contribution to the quest for a more sustainable approach to the exploitation of these valuable resources.

Measuring gas levels in oil, gas and mining plants for many reasons

In the oil, gas, and mining industries, various processes like extraction, refining, transportation, and storage result in the production or release of different gases, such as methane (CH4) and carbon dioxide (CO2). Monitoring gas concentrations at different stages is crucial to identify inefficiencies and prompt corrective actions.

Furthermore, measuring gases helps anticipate and prevent equipment failures arising from wear and tear or malfunctions. Early detection, such as monitoring hydrogen sulfide (H2S), enables maintenance teams to address issues before they escalate, reducing downtime and production interruptions.

Moreover, controlling gas levels is essential to minimize contamination and enhance product quality. For example, managing methane and CO2 levels in the anaerobic digesters of biogas plants can significantly improve the overall quality of the end product, biomethane.

Meanwhile, given the handling of hazardous substances, safety is a top priority in these industries. Real-time gas monitoring systems can quickly detect leaks or dangerous accumulations, reducing the risk to workers and neighboring communities.

Additionally, accurate gas measurement ensures compliance with environmental regulations, showcasing a commitment to environmental stewardship and fostering trust with stakeholders. Regular monitoring and reporting of gas emissions align with public health and environmental protection goals, which are integral to these industries’ responsible practices.

Our related article

Our expertise:

the non-dispersive infrared

spectroscopy

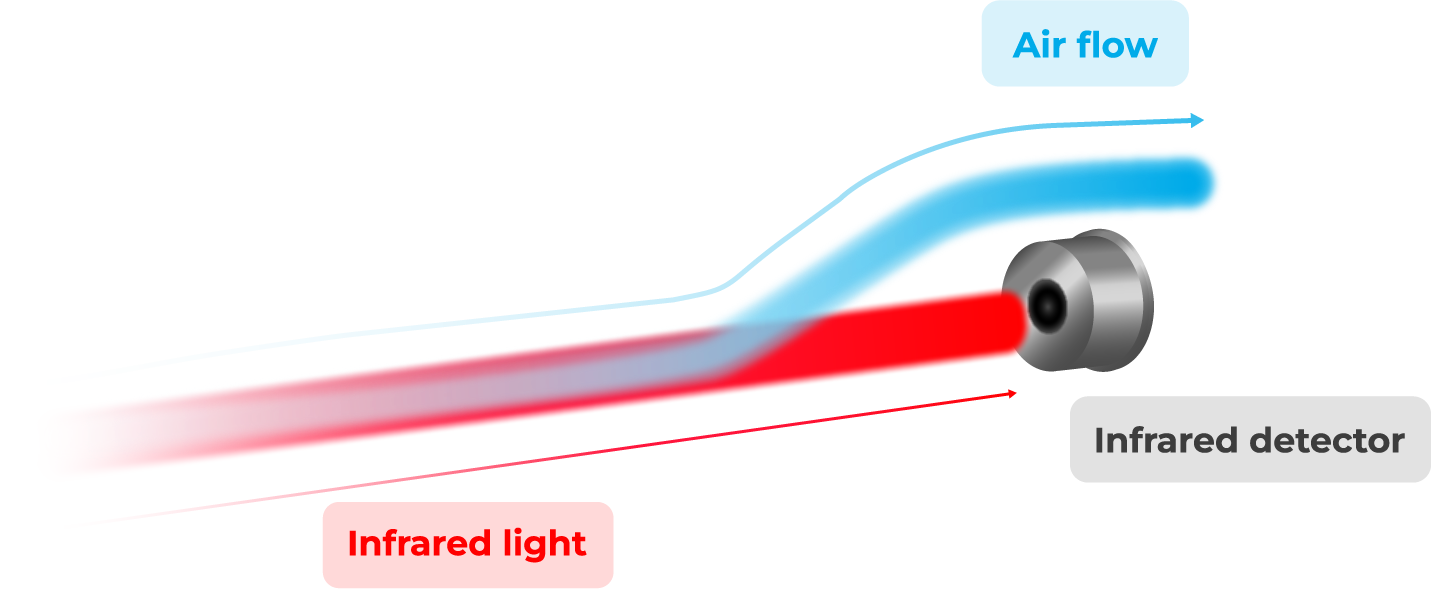

A non-dispersive infrared sensor consists of a detector that measures the amount of infrared light at a specific wavelength that is absorbed by a sample.

An infrared light passes through the chamber to the detector. The gas of interest causes an absorption of energy at a specific wavelength. This attenuation is measured by the detector to determine the concentration of the gas. The detector is preceded by a bandpass optical filter that eliminates all other wavelengths that the selected gas molecules may absorb.