Methane measurement

Discover the uses of our NDIR methane sensor on this page.

Methane measurement

Methane is a colorless and odorless gas that is the primary component of natural gas. It is the simplest hydrocarbon, consisting of one carbon atom and four hydrogen atoms, and has a chemical formula of CH4. Methane is a potent greenhouse gas, with a global warming potential 25 times greater than carbon dioxide over a 100-year time horizon. It is produced naturally in a variety of biological and geological processes, including the digestion of food by cows and other ruminants, the decay of organic matter in landfills, and the geological processes that produce fossil fuels.

SCIENCE

How to measure CO2 in breath with infrared spectroscopy?

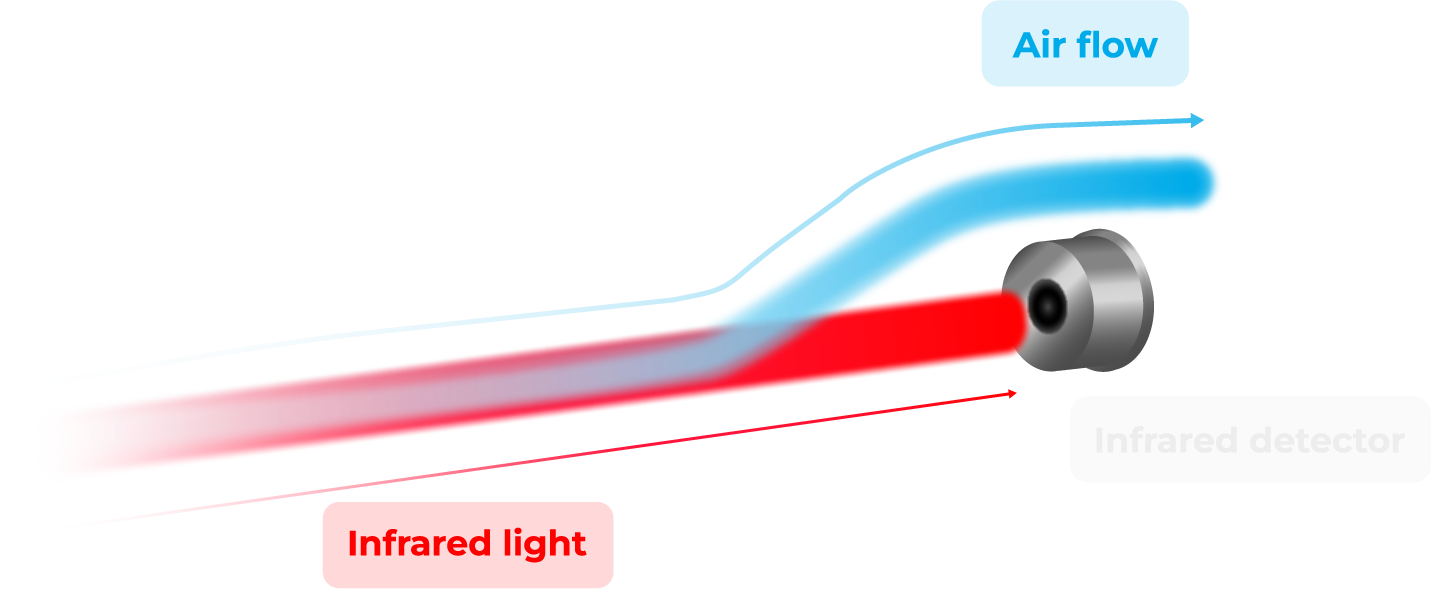

NDIR stands for “Non-Dispersive Infrared” and is a technology used in gas sensing that measures the concentration of a specific gas by detecting its absorption of infrared radiation. NDIR sensors are commonly used for monitoring the concentration of gases in air, including CH4.

To monitor methane (CH4) in the air with an NDIR sensor, the air is first collected and directed towards the sensor. The sensor contains an infrared light source that emits a beam of infrared radiation at a specific wavelength, which is absorbed by the CH4 molecule. The sensor then detects the amount of infrared radiation that is absorbed by the CH4, and uses this measurement to calculate the concentration of the gas.

NDIR sensors are preferred for CH4 monitoring in exhaled air because they are accurate, reliable and can detect CH4 on a large concentration level, in parts per million (ppm) or % range. They are also relatively easy to use and require minimal maintenance, making them a popular choice in energy and agriculture settings. Additionally, NDIR sensors are not affected by changes in temperature, pressure, or humidity, which can sometimes interfere with other gas sensing methods.

NDIR sensors are commonly used for methane detection in a variety of applications, including biogas production, landfill gas monitoring, and natural gas pipeline monitoring. They are also used for monitoring methane emissions from industrial processes, such as oil and gas production.

Biogas production

processes

During anaerobic digestion, microorganisms, primarily bacteria, break down organic matter into simpler compounds through a series of metabolic processes. One of the metabolic pathways involved in anaerobic digestion is the production of methane. Methane is produced when microorganisms called methanogens break down organic compounds such as acetic acid, hydrogen and carbon dioxide.

The methane produced during anaerobic digestion is the main component of biogas and is what makes it a useful energy source. In addition to methane, biogas also contains other gases such as carbon dioxide, nitrogen and hydrogen sulfide, as well as traces of other gases.

Methane production during the biogas process is influenced by a variety of factors, including the type and composition of the organic material being digested, the temperature and pH of the digester, and the activity of the microorganisms involved in the process. By controlling these factors, operators can optimize the biogas production process and increase the yield of methane gas.

Measuring methane emissions at biogas plants is therefore important for several reasons. First, because methane is a much more potent greenhouse gas than carbon dioxide, it is important to measure its emissions to ensure that the biogas plant does not contribute to global warming. Measurement is also crucial to ensure that the plant is operating properly and to detect leaks or technical problems. In addition, it can help optimize the processes and efficiency of biogas plants. By regularly monitoring methane emissions, biogas plant operators can identify areas where improvements can be made to reduce methane losses and improve plant efficiency. Finally, measuring methane emissions at biogas plants is often a regulatory requirement as governments and local authorities seek to limit greenhouse gas emissions as part of their efforts to combat climate change.

The different stages of biogas production are as following:

- Pre-treatment of organic matter: Organic matter such as food waste, green waste, sewage sludge, etc. must be sorted and pre-treated to remove impurities, non-biodegradable matter and elements that may interfere with anaerobic digestion, such as heavy metals, plastics, etc.

- Anaerobic digestion: Anaerobic digestion is the degradation of organic matter by microorganisms in the absence of oxygen. The micro-organisms produce biogas as a by-product of this degradation. Anaerobic digestion can last from a few days to several weeks, depending on the digestion conditions.

- Biogas production: The biogas generated is mainly composed of methane (CH4) and carbon dioxide (CO2), with small amounts of other gases such as hydrogen sulfide (H2S) and ammonia (NH3). The composition of the biogas varies according to the composition of the digested organic matter.

- Biogas storage and treatment: The biogas produced is stored in a tank before being treated. The treatment includes the removal of H2S and water, and the compression of the biogas to make it usable.

- Biogas use: Biogas can be used as a fuel to produce heat and electricity or as a fuel for vehicles. The residue of the digestion process, called digestate, can be used as fertilizer in agriculture.

Oil, gas and mining

industries

Leaks can occur for a variety of reasons such as equipment wear and tear, corrosion, mechanical failure, human error, or equipment design. Leaks can also occur during the extraction, production, processing, transportation, and storage of natural gas. Because of the invisibility of methane, leaks can be difficult to detect without proper measuring instruments.

Methane emissions have significant environmental and climate impacts. Methane is a much more potent greenhouse gas than carbon dioxide and has a shorter lifetime in the atmosphere. This means that methane has a greater impact on short-term climate change. Methane emissions can also contribute to air and water pollution.

Hydrogen production

processes

Methane releases in hydrogen production process

Methane is a key component of natural gas and is often used as a raw material in the process of hydrogen production. Indeed, extracting hydrogen from organic compounds requires breaking the strong bonds between carbon and hydrogen. To achieve this, a series of high-temperature chemical reactions, often in the presence of catalysts, are used.

One technology used for this purpose is reforming, which involves reacting methane with water to produce a synthesis gas containing hydrogen. This is the technology mainly used in industrial hydrogen production.

Operation of steam reforming

This method uses high-temperature steam (700-1000°C) to produce hydrogen from a source of methane, such as natural gas or coal. The two elements combined with a catalyst induce a reaction at a pressure of 3-25 bars, which generates CO, CO2, and hydrogen.

In a second step, called “water-gas shift reaction,” the hydrogen content is further enriched. During this step, a reaction is induced between steam and CO, again with the help of a catalyst. This results in a small amount of heat and CO and a large amount of hydrogen.

The chemical formulas for this process are as follows:

- Steam methane reforming: CH4 + H2O → CO + 3H2

- Water-gas shift reaction: CO + H2O → CO2 + H2

Steam methane reforming is an efficient process, but unfortunately very damaging to the environment because of the uncontrolled release of methane. For every kilogram of hydrogen produced by this method, no less than 7 kilograms of CO2 are released.