Fruit ripening optimization using gas sensors

Innovation in food preservation, particularly for fruits and vegetables, is vital in the face of rapidly changing consumer habits and the growing challenges of food safety, sustainability and waste reduction. These advances concern not only our food, but also our environment, economy and health.

The ripening of horticultural products, a crucial stage in the supply chain, requires particular attention to guarantee their quality and meet consumer expectations. In this context, gas sensors are essential to ensure proper ripening and extend the shelf life of these products.

Gas sensing during fruit ripening processes : benefits

- Precision control

Gas sensors allow growers and suppliers to monitor and control levels of gases such as ethylene, carbon dioxide and oxygen in ripening or cooling chambers with exceptional precision. This precision control ensures that fruit and vegetables ripen at the desired rate, reducing waste and optimising the use of resources. By closely monitoring gas levels, growers can intervene quickly to maintain optimum conditions for produce, improving overall quality and shelf life. - Preserving quality

Gas sensors make a significant contribution to preserving the flavour, texture and appearance of horticultural products. By maintaining an ideal gas composition in storage or ripening chambers, these sensors help prevent premature ripening, rotting or loss of quality. As a result, fruit and vegetables retain their freshness and nutritional value for longer, resulting in better quality products that are more attractive to consumers. This is particularly important for maintaining product integrity during storage, transport and presentation in retail environments. - Energy Efficiency

Gas sensors play a key role in promoting energy efficiency within horticultural operations, particularly in ripening chambers. By continuously monitoring gas levels and adjusting them as needed, these sensors facilitate the optimal use of energy resources. Automated control systems can precisely regulate gas concentrations, thereby reducing unnecessary energy consumption and associated costs. Additionally, by minimizing fluctuations in gas levels, gas sensors help stabilize environmental conditions within chambers, further enhancing energy efficiency. This not only benefits the bottom line of businesses but also contributes to sustainability efforts by reducing carbon emissions and overall environmental impact.

Application example: monitoring the apple ripening process

Apples are generally harvested before they reach full ripeness to extend their shelf life during storage and transport. This fruit, one of the most widely consumed in the world, requires special attention to maintain its freshness and quality.This is made possible by the use of gas sensors in specialised ripening chambers. These sensors precisely regulate the levels of oxygen, carbon dioxide and ethylene, as well as humidity and temperature, creating the ideal environment for the apple to ripen evenly. This ensures that the apple retains its crispness and develops the desired colour and flavour profiles, meeting the highest quality standards.

Thanks to this advanced technology, growers can extend the availability of apples on the market, meeting consumer demand throughout the year. By precisely monitoring ripening conditions, these sensors maximise yields while minimising losses, ensuring an efficient and profitable supply chain for apples and similar products.

EXPERTISE

Specific gas sensing : our expertise

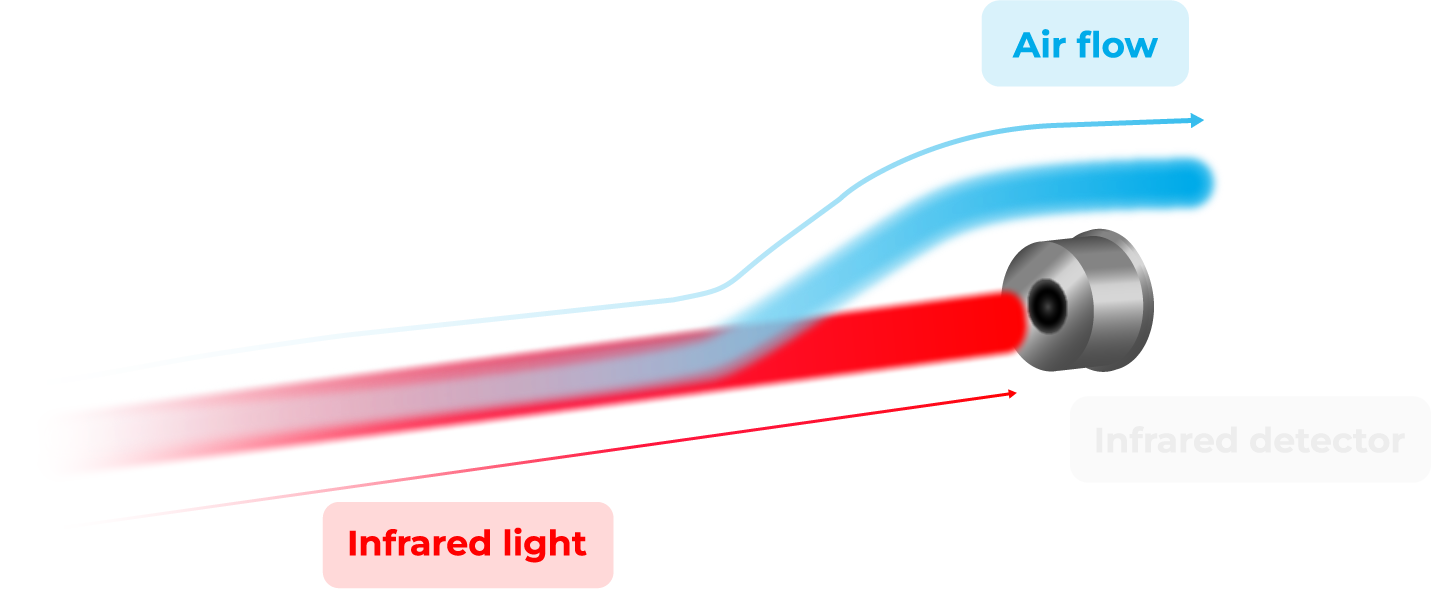

Our gas sensors use the infrared spectroscopy technology to detect and measure the concentration of several gases. These sensors are integrated into ripening chambers and connected to control systems that adjust gas levels based on real-time data.

Our non-dispersive infrared (NDIR) sensor includes a detector measuring specific-wavelength infrared light absorbed by a sample. Infrared light passes through a chamber to the detector, and gas absorbs energy at that wavelength. The detector measures this attenuation to determine gas concentration, aided by a bandpass optical filter that removes unwanted wavelengths absorbed by the gas.

Gas sensors are revolutionizing the horticultural industry, enabling precise control of the fruit and vegetable ripening process. Their ability to maintain the ideal gas composition means higher-quality produce, longer shelf life, less waste and lower energy consumption.